Boots & Bellows

Multigenerational technology for long-lasting performance and durability

The durability, temperature, and chemical resistance of our thermoplastic elastomers enables the design of compact, more cost-effective boots to help reduce vehicle weight and improve fuel efficiency.

Proven by decades on the road

The inherent wear resistance and strain elasticity of DuPont™ Hytrel® combined with its superior mechanical properties, grease resistance, and flex fatigue help improve the durability of constant velocity joint (CVJ) boots. The vehicle’s rotating shaft also is protected from road debris and axle grease.

After more than 30 years of development experience and over one billion CVJ boots manufactured with DuPont materials, we continue to evolve our non-squeak materials for electric vehicles. Processed via press-blow, injection-blow or direct-injection molding, our materials also offer high-flow and high- temperature-resistant materials with good fatigue performance and grease compatibility.

Typical applications include:

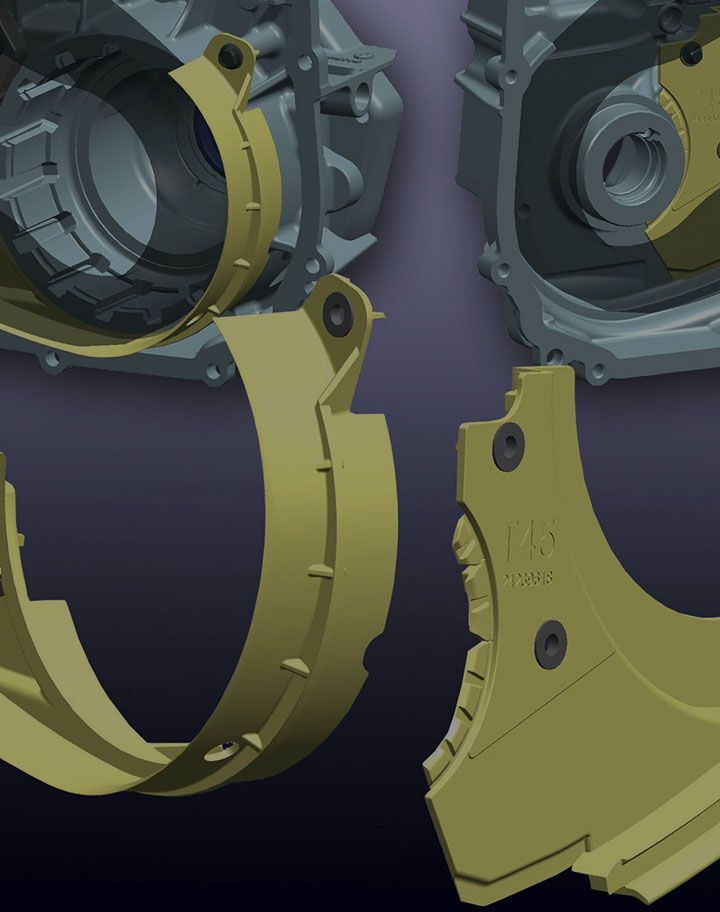

- Front and rear driveline half-shaft outboard and inboard CVJ boots

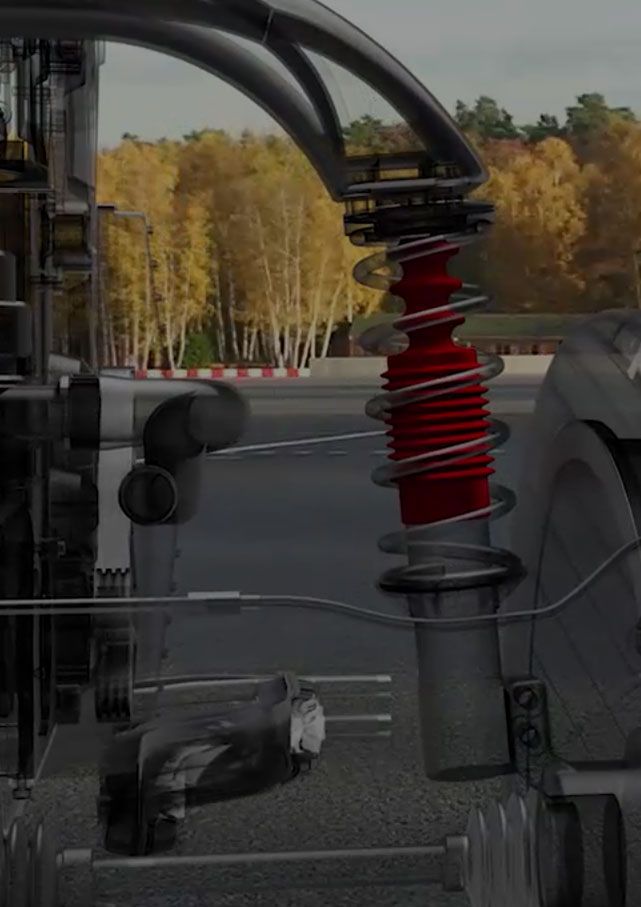

- Stabilizer link dust cover bellows

- Steering rack and pinion boots

- Suspension dust cover bellows, jounce bumpers, rebound bumpers, and air springs

- Transmission propeller shaft boots

DuPont capabilities

Our team includes application development engineers and technical experts in materials, advanced CAE, processing, parts prototyping, and testing. We collaborate with manufacturers of machines, parts, and vehicles—as well as tier suppliers—to help create the best solution for each boot.

Contact us to learn about our latest developments.